Is that an Earthquake or Just the Streetcar?

Tackling Noise & Vibration Testing for LRT

Do Light Rail Transit (LRT) vehicles shake the ground they travel on? Can you feel an LRT in your house while you are trying sleep? Can an LRT shake your house more than an earthquake?

The answer is of course, yes, otherwise I wouldn’t be explaining how an LRT can produce vibration and ground-borne noise along its alignment and how we at Aercoustics can ensure this doesn’t happen. Vibration and ground-borne noise mitigation is a requirement for all project agreements on current LRT projects in Ontario – so it’s not a matter of if, it’s a matter of when you need to know.

How much noise and vibration is too much?

As part of all the recent round of government funding to improve public transit in the Greater Toronto Area (GTA), there are a half-dozen, large-scale, LRT transit projects currently in the works, all at various implementation stages. Typically, as part of these projects, the project agreement dictates how much noise and vibration an LRT system can generate.

Selecting LRT Track-type to Minimize Vibration

For a new design-build transit system, the main factors that determine how much vibration an LRT generates are the track-type and what happens to the vibration as it travels between the track and the receiver point. LRT projects can have various track-types which are mainly governed by maintenance needs and vibration. Most LRT track are of the embedded concrete type with an encapsulated rubber boot to limit vibration, but in certain areas of the alignment, this isn’t enough.

Where LRT systems are in close proximity to sensitive spaces, it is imperative that the track-type has sufficient capability to reduce vibration transmission into the ground to ensure satisfaction with the project agreement. The question is, how do we know what track-type to use? And the answer is simple…

Hire an Expert in Vibration Testing for Transit

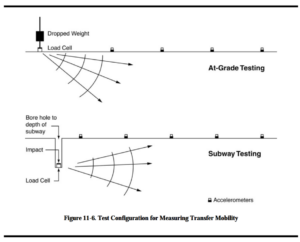

That’s where the mouthful of “Vibration Propagation Testing” or “Soil Vibration Propagation Testing” or “Federal Transit Administration Detailed Vibration Testing” or “Ground Impact Testing” or “Drop Testing” or anything along those lines comes in, and then you should think of us. BTW, I dare you to say any of those quoted phrases 5x fast without mishap. If you do, email me and I’ll take you to lunch…but I get to pick the joint.

Learn How Track-type Impacts Transit Design & Maintenance

Whether you are civil, geo-tech, rail, constructor, operator, or maintainer, you should know how track-types are determined. It will not only assist you in your job, but you’ll be able to explain to others about implications and risks to design changes. Especially considering the 30-year operating and maintenance contracts, the selection of track-type couldn’t be more important. In a world where cost is the driving factor for the winning proponent, a holistic view is needed as rails and wheels wear over time, which leads to higher levels of vibration along the alignment. Consideration for an improved track-type to minimize vibration can significantly reduce maintenance costs over the contract period.

This is especially critical as design and construction teams typically have separate interests than operating and maintenance teams, which is often how the division of work and contracts are separated within the consortium of companies chasing each LRT project. Just imagine you’re given an LRT system that you can’t drive on for more than a year until you’ve hit your vibration quota – then you have grind the rails way more than you budgeted due to vibration constraints in the track bed.

Noise & Vibration Testing for Light Rail Transit

So…how do we do it? Well, it’s pretty simple actually. We shake the earth, and see how it responds! With our testing capabilities, we have the ability to determine exactly how LRT vibration travels through the ground between a source, the LRT vehicle, and the receiver – a bedroom, a recording studio, a concert hall, a hospital, and anywhere sensitive along your alignment. This is how we form the basis for the required track-type in sensitive areas along the alignment. We can also assist your team with the detailed design of the vibration mitigation systems with consideration of the long term, typically 30-year, operation period which will save on costs and properly keep the noise and vibration system health in check, not only improving your overall project budget, but also providing significant value to the end-owner.

For more information, please contact me at [email protected]

Long live the LRT, but let’s keep it quiet!